Danfoss Gear Motors

GearMe: ideal choice for a wide range of applications - from small to medium and large off-highway vehicles. Available in 3 frame sizes and many features, from the simplest gear motor to the most complex fan drive, including ultracompact option.

Rugid: specifically designed for demanding mobile applications where maximum performance is required at peak power levels and operating temperatures.

Gear Motor Gr. 1

- A high efficiency and a light weight aluminum construction

- Pressure balanced bearing blocks for maximum performance across operating range

- Teflon® coated bushings extend life under extreme temperature, pressure and speed conditions

- One piece gears minimize deflection under pressure

- An excellent starting torque

Specifictions

- Motor displacement range 2,6 up to 12 cm³/U

- Pressure up to 270 bar

Gear Motor Gr. 2

- A high efficiency and a light weight aluminum construction

- Pressure balanced bearing blocks for maximum performance across operating range

- Teflon® coated bushings extend life under extreme temperature, pressure and speed conditions

- One piece gears minimize deflection under pressure

- An excellent starting torque

Specifications

- Motor displacement range from 6 up to 25 cm³/U

- Pressure up to 280 bar

Gear Motor Gr. 3

- A high efficiency and a light weight aluminum construction

- Pressure balanced bearing blocks for maximum performance across operating range

- Teflon® coated bushings extend life under extreme temperature, pressure and speed conditions

- One piece gears minimize deflection under pressure

- An excellent starting torque

Specifications

- Motor displacement range from 22 up to 90 cm³/U

- Pressure up to 270 bar

Fan Drive Gear Motor Gr. 2

- An integrated dust cover to extend product life by preventing dirt ingression across the shaft seal

- An enhanced gear teeth machining and special coating to reduce noise levels to boost operator comfort

- EH proportional valve integrated in the rear casting to provide more uniform performance over the entire operating temperature range

- PLUS+1® Compliant technology to ensure all electro-hydraulic products integrate seamlessly in a customized control system

Specifications

- Motor displacement range from 8 up to 25 cm³/U

- Pressure up to 270 bar

Fan Drive Gear Motor Gr. 3

- An integrated dust cover to extend product life by preventing dirt ingression across the shaft seal

- An enhanced gear teeth machining and special coating to reduce noise levels to boost operator comfort

- EH proportional valve integrated in the rear casting to provide more uniform performance over the entire operating temperature range

- PLUS+1® Compliant technology to ensure all electro-hydraulic products integrate seamlessly in a customized control system

Specifications

- Motor displacement range from 22 up to 44 cm³/U

- Pressure up to 270 bar

D Series Cast Iron Group 2.5 Motor

Rugged, dependable performance under high pressure

- 20% smaller than conventional gear products, high power density in a small package for easy installation in optimized machines

- Thrust plate design for high efficiency over a wide temperature range

- Teflon® coated bushings for extended life under extreme temperature and pressure conditions

- Viton® seals are standard to sustain higher temperature and fluid capabilities

- Broad range of shaft drives, integrated valves, and side or rear port options gives great flexibility in system design.

- Cast iron design for maximum efficiency, dependability, durability and reliability in performing continuous operation in heavy duty applications with severe duty cycles and temperature conditions, all within the industry leading package size and power density.

Features and benefits

- Thrust plate design for high efficiency over a wide temperature range

- Teflon® coated bushings for extended life under extreme temperature and pressure conditions

- High strength cast iron construction for efficient performance in continuous operation

- Easy installation in optimized machines due to compact, power-dense design

- Viton® seals are standard to sustain higher temperature and fluid capabilities

Specifications

- Motor displacement range from 14 up to 45 cm³/U

- Pressure up to 303 bar

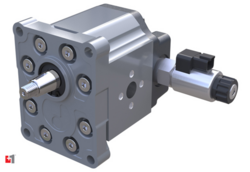

D Series Cast Iron Fan Drive Gear Motors

For fan drive applications, a variety of valve options are offered for great flexibility. This allows for integrated reversing, proportional relief, fixed relief, and anti-cavitation valves.

Specifically designed for demanding mobile equipment applications where maximum performance is required at peak power levels and operating temperatures. Our cast iron motors ensure great productivity and excellent fuel efficiency along with reduced vehicle emissions.

- 20% smaller than conventional gear products, high power density in a small package for easy installation in optimized machines

- Thrust plate design for high efficiency over a wide temperature range

- Teflon® coated bushings for extended life under extreme temperature and pressure conditions

- Viton® seals are standard to sustain higher temperature and fluid capabilities

- Broad range of shaft drives, integrated valves, and side or rear port options gives great flexibility in system design.

- Cast iron design for maximum efficiency, dependability, durability and reliability in performing continuous operation in heavy duty applications with severe duty cycles and temperature conditions, all within the industry leading package size and power density.

Features and benefits

- Thrust plate design for high efficiency over a wide temperature range

- Teflon® coated bushings for extended life under extreme temperature and pressure conditions

- High strength cast iron construction for efficient performance in continuous operation

- Easy installation in optimized machines due to compact, power-dense design

- Viton® seals are standard to sustain higher temperature and fluid capabilities

- A variety of integrated valve options

Specifications

- Motor displacement range from 14 up to 45 cm³/U

- Pressure up to 303 bar